Primii 1.000 de oameni care vor folosi linkul vor primi o lună de probă gratuită a Skillshare https://skl.sh/mjsailing05231 Ura, am pus jos șlefuitoarele! Pentru câteva zile oricum. Acum că ne aflăm în acel punct dulce de temperatură, putem trece la aspirarea unor articole mai mari pentru catamaranul nostru. Trecem la lucru la construirea grinzii structurale care va sta în partea din spate a cabinei noastre. Deoarece călătorul nostru va sta deasupra acestuia și va fi înșurubat în el, trebuie să ne asigurăm că este foarte puternic. Începând cu o foaie de scândură de coosa de 4×8, (o spumă foarte densă), o tăiem în fâșii de 3″ lățime și apoi eșalonăm îmbinările pentru a obține o lungime totală de 10,5 inchi. Apoi le stivuim una peste alta pentru a face 7. straturi. Lipirea tuturor implică rășina noastră îngroșată pentru a începe, și apoi mai multe straturi de fibră de sticlă unidirecțională și dublă. sper sa iti placa!

source

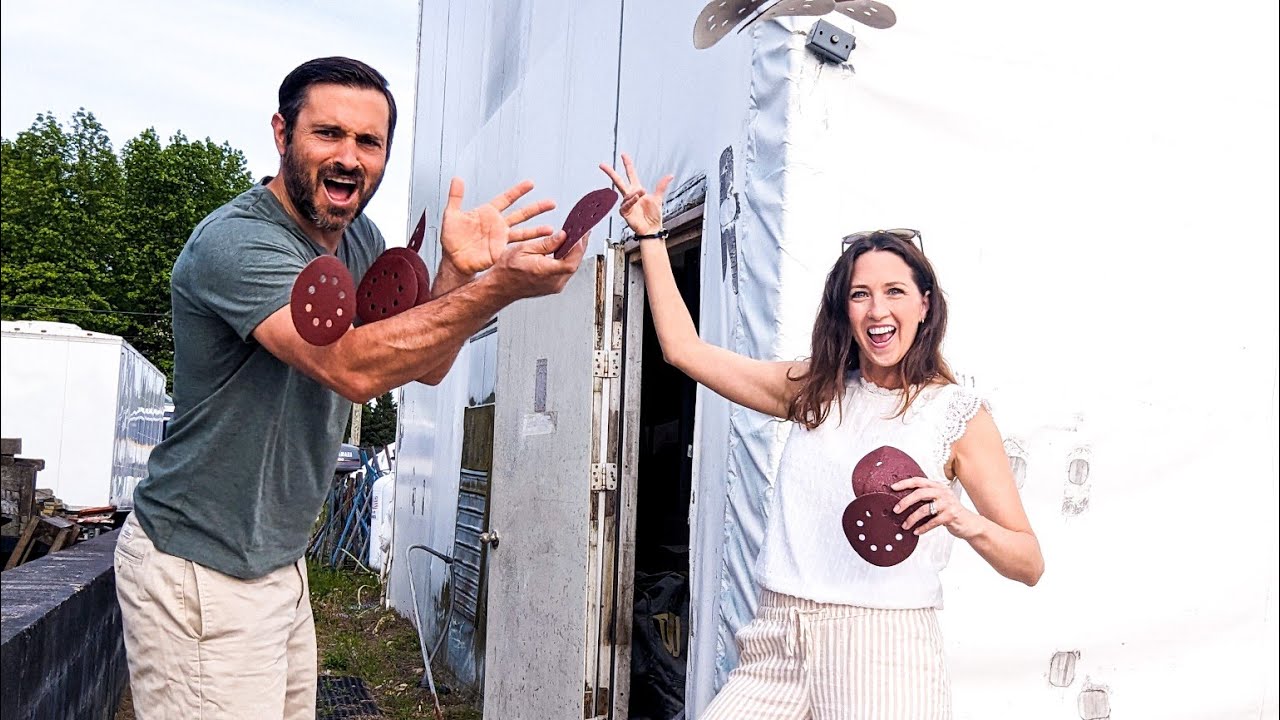

Cel puțin nu șlefuim!! (Pentru că suntem în saci cu vid) MJ Sailing – Ep 284

46 thoughts on “Cel puțin nu șlefuim!! (Pentru că suntem în saci cu vid) MJ Sailing – Ep 284”

Comments are closed.

✌️❤️🙏 the best I can offer. I’ve always been one to plan the work then work the plan, but you two make me look like a slug. ✌️❤️🙏 oh yea a little 🍺🍷🍸🥃 helps. 😎

I think if you got the tubes but A. try a small fan on the open end ( hair dryer even) as you slide the tube on, that way it won't touch and pull the layers, or B. cut the tube in half for really long objects and use the fan inflation approach. A lot less tape and fuss

👍

Jessica learned how to say 'Flange." I guess that is what happens when a girl is gone for too long from Michagan 🙂

I think you to want to look at life on the halls and see what he does to his catamaran that he’s building. He does such a great job and everything and takes half the time. I think it takes you too but anyway you’re doing a great job, but I would pay attention to life on the halls.

Great choice with the Coosa over the cedar. Did Andy Miller give you this idea? A little surprised Max Cruise does not do this themselves (name me one old boat that has not had to replace rotted wood where high stress fittings are anchored through the deck into it???). 2 questions: 1) How did you transfer the curves of the hull to the beam in 3 dimensions? 2) Does gravity matter to the curing process? Did you rotate the beam while it was curing both while the compressor was on and once again while it was sitting in the sun; e.g., 15 minutes on a side?

That's going to be a strong beam. Nice work.

Stay safe and we'll see you next week.

Too strong is just right. Good tag team glassing! I've been following since Elements was a gutted hull and have not yet been disappointed.

Matt, Where you have install hardware in beam, try and run heavily loaded fasteners THROUGH beam so a washer/plate and nut or bolt head can do the work, separately from a well bedded sealer or even a polymer sleeve… this is so you can seal the beam while not being strained by loads.. ie sealed areas floating and allowing expansion/contraction to occur normally without affecting bedding compounds or a sleeve being placed in shear loads.

Gold in Our Pockets – by Tigerblood Jewel – was the name of that song near the beginning. Pretty catchy, I had to search a bit.

That blue boat in the background is georgous did you put that in the video on purpose I'm sure I'm not the only one impressed, nice work guys gals

Week after week, what impresses me about these videos is the editing. It is so well done! No matter what is happening in the video, the editing always supports the story. There is very little fluff. The music choices are fresh and compatible with the story. The care you put into these videos matches the care you are putting into the boat. I always look forward to the videos. They are a joy to watch.

If you have many of those seems a gel peeler would be a great investment. They are a tool often used for peeling gelcoat to do osmosis repairs but have also seen them used for doing this job joining seems.

Hey guys, great video. Very interest process.

Just wanted to remind you to go around and check the expiration dates on all of your fire extinguishers. If you want to, you can call a local company to come out and inspect the extinguishers. For a very reasonable fee, these companies will take the extinguishers that are out of date, service them and leave an extinguisher, of the same kind in its place while yours is being serviced. Either after 3 years or 5 years, most extinguishers have to be completely rebuilt. With all of the highly flammable products you are using, it is extremely important to make certain all of your fire fighting equipment is in good working order. A few hundred dollars could save your life and your boat too. Good luck!!

I can see another 2 to 3 years of work here, massive amount of work and resources used in this project by unskilled workers trying to learn on the job, when you should have had Professionals build the whole thing.

nice

awesome thanks

I'm so proud of you two! You kick @$$. Every week is another nugget to enjoy.

I know you are American, just maybe stop translating into American measurements? It is a boat from metric plans, it anyone wants to replicate your your journey with the same plan, maybe time to stick to metric.

(It is by far the superior system)

Did you have a heavy night last night; white powder on your nose!

Just to let you know the respirator without the p95 cloth filter are still letting fibers and dust through, that voc filter only gets vapors you need both.

good music!

Superb

How are you coping with the inflation issues?

Touches like choosing a rot proof inside to the beam show the care you are taking with this build. Too many GRP boats have pieces of wood in crucial places, and take a disproportionate amount of work to fixed years later. Good to see you have warmer weather to make progress with these bigger jobs.

Cheapen a build by using wood is shortcut one should never take. Drive a screw into wood and it's now subject to rotting from the inside out. By the time you see the rot it's always too late to do anything but replace.

Thinking outside the box I now use Totalboat penetrating epoxy for wood structure outside the house. Elevated patio deck, patio cover, pool gazebo, decorative fencing, and greenhouse now match. Getting stain/paint to adhere to it after is another topic. Great product, but like you I refuse to you I refuse to use wood on my catamaran.

Most impressed by how you two refuse to take short cuts. "More or Less" never enters your vocabulary.

Coosa you say. How does Coosa compare to Star Board?

great to see vetus and total boat on the wall -paying it back win win – well done

What? When did I miss the advertising banners? Heck yeah, get busy and work in some other companies – water makers, navigation, solar panels, etc.

Great work! You could use a heat sealer to seal the plastic, might be a cheaper alternative to tape too!

BTW, did you consider a carbon beam?

Easy peasey beam construction, not, you guys go the extra mile in fabrication. Can’t wait till our hard work pays off and we are sailing. Thanks.😎

You should end up with a very strong beam and one you don’t have to worry about rot years from now.

I have seen some videos of people that are taking off the gelcoat, and they use a special machine that is made for it. I think it is kind of like a planer.

What's with the gaps on the sugar scoops?

That beam looks great. Good and strong.

You do such a great job explaining what you're doing and why. Then you video it so clearly and edited it so cleanly. Thank you. It really is enjoyable to watch and listen.

well done on that fibre glassing the beam! That was a new one for me 🙂

Great Video !

And the beat goes on! Great work Matt and Jess!

and i thought this was the sanding channel 🙂

Cheers to you.

So exciting! Getting 'er done!

So while I'm watching this I'm just wondering. What's your next boat going to be? 🙂

I am amazed that you guys are actually building your own boat, the skills and talents you must have or learnt is mind blowing. The boat looks awesome. There must be so much physical effort as well. I’ll take my hat of to you both for your sheer determination.

looks very strong