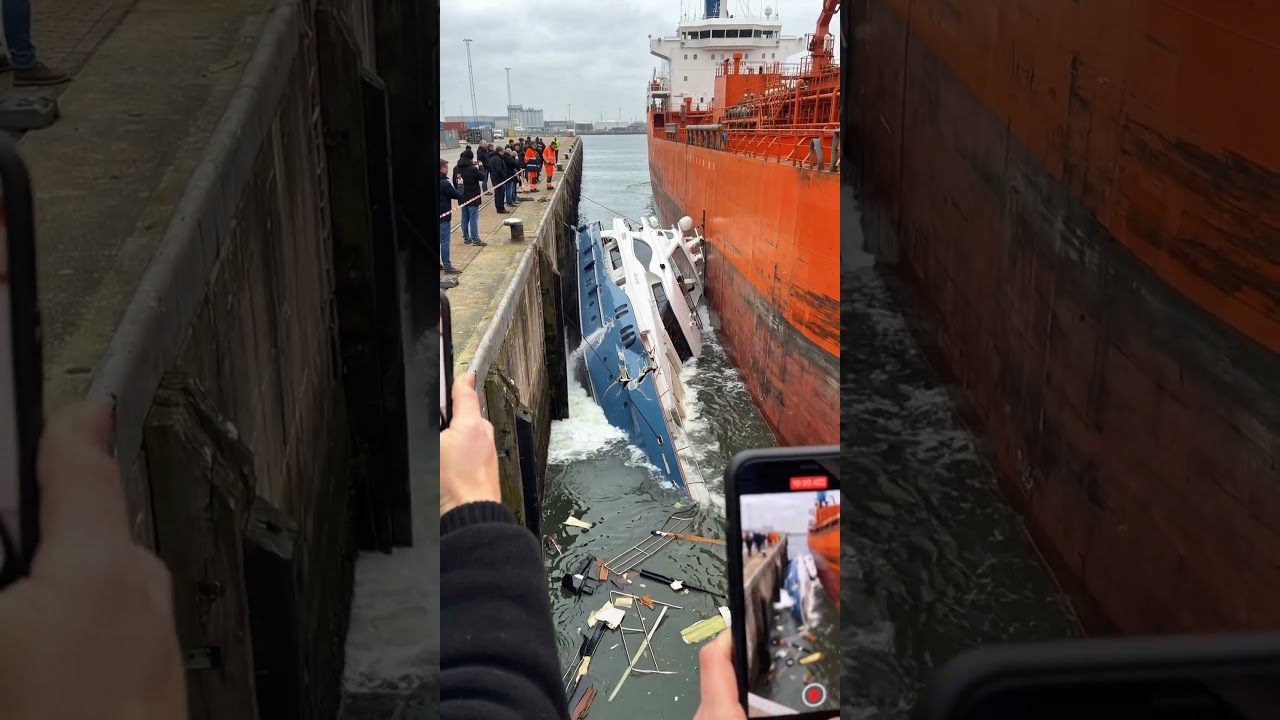

Aducerea Yabá de la epavă la vis! Episodul 152 În acest episod al restaurării bărcii noastre, îl pregătim în sfârșit pe Yabá să se îndrepte spre orizont! 👉 ABONAȚI-VĂ pentru a nu rata noile episoade: https://bit.ly/3dI3hBn PUTEȚI SUSȚINE PROIECTUL: 👉 Devenind patron – alăturați-vă pentru a debloca conținut exclusiv: https://www.patreon.com/sailingyaba 👉 Prin donații Paypal: https://bit.ly/3kR4Ezo sau sailingyaba@gmail.com 👉 Purtând produsele noastre: https://shopsailingyaba.com/ 👉 OBȚINEȚI INSTRUMENTELE NOASTRE PREFERATE: https://www.amazon.com/shop /sailingyaba Suntem pentru totdeauna recunoscători tuturor celor care ne trăiesc visul alături de noi ♥️ 🇧🇷 Legendas em Português em todos os episódios! 🇪🇸 Subtitluri în spaniolă în toate episoadele! 💙 Cine suntem? Suntem Ben și MP! Recent am decis să achiziționăm o goeletă din lemn cu doi catarge în Brazilia. Detaliul distractiv despre povestea noastră este că barca pe care am cumpărat-o se scufunda și se baza pe multe pompe de santină pentru a supraviețui, așa că a trebuit să o ridicăm pe uscat pentru a începe o reparație completă. Odată ce barca a fost ridicată (pentru prima dată în viața ei) ne-am dat seama că munca necesară a fost mult mai mult decât se aștepta. Între eliberarea sau acceptarea provocării, am decis să alegem a doua variantă. Urmărește-ne când îl readucem la viață pe Yabá cu ajutorul unei echipe uimitoare de constructori navali tradiționali, împărtășind fiecare fază a procesului, depășind culmile și coborâșurile și distrându-se pe parcurs. Mai multe despre noi: 👉 Despre noi + Întrebări și răspunsuri https://youtu.be/TldDlohjwTs 👉 mai multe informații despre proiect http://www.sailingyaba.com 💙 Mulțumiri masive echipei noastre uimitoare de dulgheri care nu ne-au dezamăgit niciodată și continuă să uimește-ne la fiecare pas al procesului: Toninho, Zeca, Hélio, Claiton, William, Nezo, Nico, Adilson, Beto și Luiz. SUNTEȚI LEGENDE!

source

În sfârșit, putem conduce barca noastră de lemn care s-a scufundat cândva spre orizont – Sailing Yabá 152

27 thoughts on “În sfârșit, putem conduce barca noastră de lemn care s-a scufundat cândva spre orizont – Sailing Yabá 152”

Comments are closed.

Huge promo alert of lithium batteries! Check Battle Born Batteries' flash sale here: https://shorturl.at/adHJK and save up to $375 on batteries and 15% off on bundles!

cool

Does the gear cog allow for rudder feedback to the helm. Or will letting go of the wheel after a turn allow it to "unturn" to the neutral point from the water pressure on the rudder? And will turning at a higher speed make it harder to turn the wheel in turning the rudder? I think rudder feedback is a good thing, and that's why I've always preferred a tiller to control a rudder. Usually the feedback is lost when the gear ratio is such that the rudder can't overcome the friction of the gear gogs and its higher gear ratio in the reverse direction of the wheel turn. Can you view the position of the top of the rudder on the transom from the helm position?

Baluster spindles are looking great!

Awesome looking helm!

Hallo Freunde,

ihr solltet unbedingt einen Spanner in das Seil einfügen. Wenn das Boot im Wasser ist wird der Widerstand dazu führen, dass die Kette überspringt. Gruß Maik

hard eye. you have a lot of slack to get out of the wire; may be prudent to insert a large spring on one strand to absorb some of the forces and ensure the wires are taut

I know, I'm nitpicking about this stove. Too thin a line. I know it has durability, but see for yourself the durability of the chain you use for this rope. Thin line – read stretchability, it always happens at the wrong moment. I would use at least 12 mm, the one you used probably weighs no more than 300 kg, 12 mm made of stainless steel. A 12 mm rope weighs almost 9000 kg, considering the surface area of your fin it is reasonable.

I have spent as long in the comments as in the video this week. Fascinating insight, You Tube is by far the best thing on the internet. Well done on creating this community of people with common interest and knowledge.

0:38: 🛠️ In this episode, the team starts connecting the steering wheel to the rudder system.

2:45: 🔧 The video demonstrates how to properly secure the steel wire clamps and fasten the nuts to ensure the steering doesn't come loose.

6:33: 🔧 Drilling higher allows the drill to avoid the cover board and the wheel can be fastened tightly.

13:23: ! The video demonstrates the process of tightening and adjusting the steering wheel in a vehicle.

18:18: 🚢 The speaker is excited about the steering wheel and the round table on their boat, and they are in the process of varnishing the wood.

23:48: 🔩 The video shows the process of installing screws and wheels in a project.

27:01: 🔧 The steering system is smooth but needs some adjustments.

Recap by Tammy AI

Don't think your wire clips should be opposite directions, and they look like they are too close together……

Brilliant looking steering wheel. Great to. see Ben developing his skills.

Para cuando toca la marea

Ben sounds like some pretty advanced comments about steering. Maybe reassess your gear👍🙏🏽

I think you should change the helm to hydraulic, there are many issues as already stated with your current system. Plus how are you going to attach an autopilot actuator to the rudder as it is now. I see there is a rudder position indicator on the helm, are you going to connect it?

You should know about what we call a "snatch block." This is a (pulley) that can be installed in the middle of rigging for whatever. The more "lines" there are the more Pulling Power you get. This is basic "block and tackle" physics. So that's something to consider too. I know you know this. So if there is a place that there may be even a slight change of direction just add a snatch block into the design. Course you've probably already solved all aspects of the "steering system." ~~ Just saying. ✨❤✨. 🇺🇸

Is it me or is that rudder woefully small for that size vessel?

Another selfie video, you dont have to interfere with what you want to show

It us yaba that is interesting, not your face.

What you have to do put in between steel wire a spring than you can span your wire

All those wires and pulleys. Hydraulic is two flexible lines and one ram.

I don't know if this was already commented below, but I would (in addition to the block (pulley) for the steering, also drive a sturdy metal tube into the hole in the transom. There will always be some rubbing of the steel cable against the wood, and the wood will loose that fight. But you can even out the playing field with such a metal sleeve.

You may also want to look to have tensioner s on the cable to catch the play in the cable. Nothing serious, just to remove the slack we see from the outside – between the transom and the quadrant: look at the trailing side.

Your steeringsystem is going to work but it is not going to last. The weakest points are the connection to the chain and the ungraded rvs shackle. combined with the slack in the steering wire its waiting for problems. When the cabel slips between the blok it wil get stuck. AlsoThere is nog friction on the steering so every wave is transvered to your steeringweel. The spokes of that wheel can hit you very hard. I would suggest that you buy a good hydraulic steering system and instal it. Or build a mechanical steeringsystem using a pitman arm.

Hi

You are using the kwadrant wrong,now you get slack in the side that is not pulling.

You should connect the PS wire on the SB side of the kwadrant and vice versa aI think

Do you think it would be best to put a stainless steel pin through the hole in the stern and then feed the cable through to reduce wear on the wood.

I would have two wires over all to give redundancy in case of one breaking. Also is there going to be an indication of the rudder direction at the control station.

Boa tarde é melhor usar um redutor rosca sem fim no mercado livre sai por uns 1000 reais (fica levinha)

The rigger who explained cable clamps to me said "Never saddle a dead horse." Put he saddle on the live end of the cable (doing the work) and the u-bolt on the dead end of the cable (loose end). If you over tighten the clamp the u-bolt can cut the cable. You don't want to do that either way, but if you do cut or weaken the dead end there is less load on it and more material left to make an emergency repair.

I would consider significantly larger diameter dyneema instead of the stainless steel wire.

But all the comments about pulley fastening strength, transom protection, connection to the chain, tensioning etc would still apply.