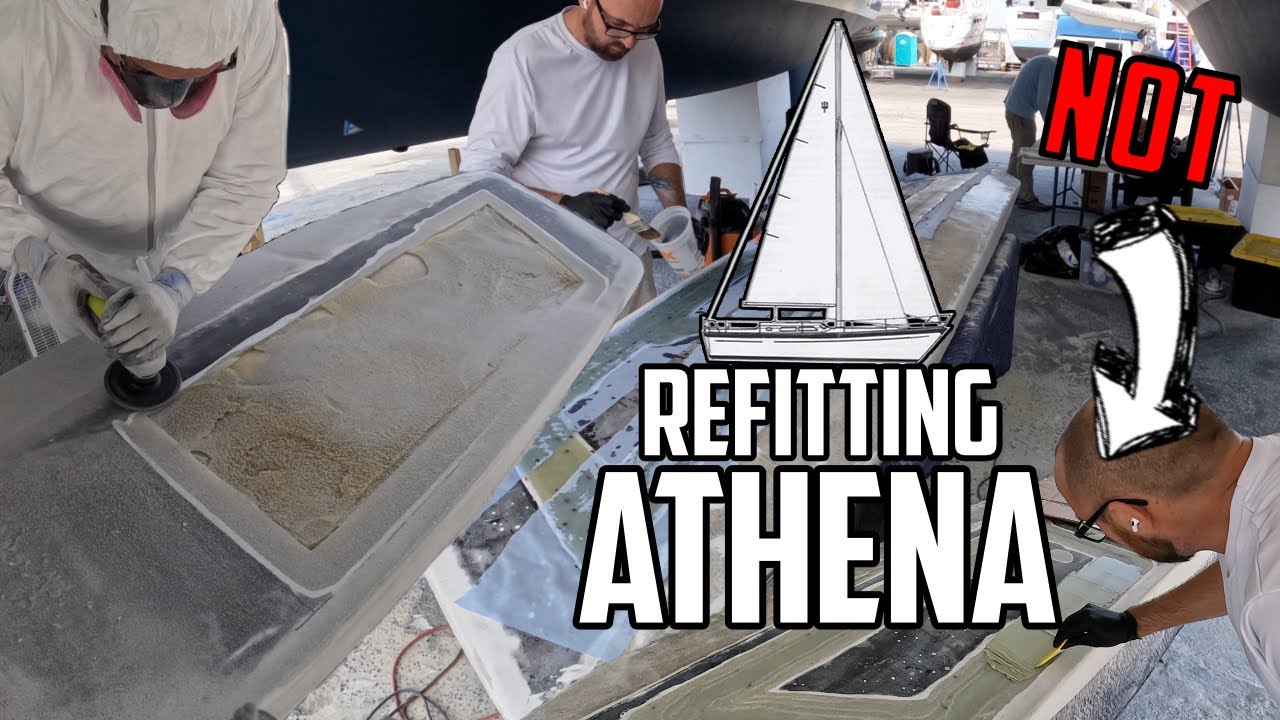

În videoclipul acestei săptămâni, este timpul să reconstruim chila. După ce am făcut refit-ul Athenei în Europa, aceasta este și prima mea șansă de a folosi câteva produse diferite de la @TotalBoat. A fost o călătorie grozavă pe calea memoriei să așezi din nou fibră de sticlă. Sunt un mare fan al vâscozității scăzute a epoxidului 2:1 de la Total Boat. Face ca umezirea fibrei de sticlă să fie un vis. Mai ales când sunteți obișnuit să lucrați cu epoxidici cu vâscozitate mai mare la temperaturi mai scăzute. ** Link-uri ** Site-ul Sail Life: https://www.saillifechannel.com/ Sail Life pe Patreon: http://bit.ly/SailLifeOnPatreon Sail Life pe Instagram: https://www.instagram.com/saillife_ Sail Viața pe Facebook: http://bit.ly/SailLifeOnFacebook Sail Life pe Twitter: http://bit.ly/SailLifeOnTwitter

source

Sail Life – Reconstruirea chilei unui catamaran de 44 de picioare

25 thoughts on “Sail Life – Reconstruirea chilei unui catamaran de 44 de picioare”

Comments are closed.

Watch out with the bonding of the keel – you don't want it to be too strong, since the keel is supposed to break off instead of damaging the hull. Don't forget, epoxy is nothing but a rather strong adhesive that adheres lots of glass (or carbon, or aramid) fibers together. Even if you use a decidedly inferior adhesive, if you adhere the keel with that amount of surface, you might end up with a much stronger bond than what holds the rest of the hull together.

That keel is not one of the heavy lead things monohulls have, it will even float, so except for the side loads when sailing, there should be very little force on the joint in normal operations.

Mads you are the best!

It's a place to see you with Epoxi and fiberglass in your hands!

Jejeje!

I need for Christmas one Brother in law likes youuu!

😂😂😂

So much plastic added to the environment, at least attach a vacuum to your sander.

Agree on all compliments about craftsmanship Mads, but you can't be serious…blowing all this epoxy dust just out in the open??? Half of the expanding foam blown away just like that. Come on. You did better than that.

A really great job, it's good to see Total Boat supporting many YouTube boatbuilding projects. I have had excellent results with Sikaflex 291 as an underwater adhesive/sealant, I have two full lengths of iroko stuck to the bottom keels of a 10 metre power catamaran that have been in place for 23 years with no problem.

Nice work.

Nicely done – such a great repair on the keel!

Eva is starting to have bad influence on him. He's starting to think in *F

😂

You just made one side of that boat a lot better than then the original.

Mads, you truly are an artist, your work is second to none.

The amount of (fiberglass) boat construction knowledge you've accumulated is just so fun and satisfying to watch. Thanks to you I've been able to become less scared of epoxy to fill some deck fastening holes; fiberglassing will be next one of those days, inevitably, and inevitably I'll turn to a Sail Life video for guidance. 🙂 Keel's looking great.

You're certainly in your natural element doing this repair, and it shows in the high quality of the episode.

Is this a project for someone else or a new boat for you?

Mads is in his happy place!! Love this stuff.

🙃🤙 nice going👍you should build yourself a full maintenance sailing ship next and sail around the globe and only do sailing ship renovations with people, oh boy how nice would that be to watch all the time🥰

I have a fiberglass car im modifying. your videos are head and shoulders above any I can find about automotive fiberglass work. just so you know 🙂

Good Job 🙂

That’s a nice professional job brother I wish you were my brother-in-law. Keep up the good work.

I was too busy enviously admiring your reclining keel creeper to notice ANY cargo ships!

Luck bro in law…

0:00: 🛠️ The boat owners are preparing to rebuild the keel of their sailboat after discovering water trapped inside.

3:57: 🔧 The video demonstrates the process of sanding fiberglass and patching up holes on the keel of a boat.

7:32: 🔧 The video demonstrates the process of reinforcing the edges of the Keel using fiberglass and thickened epoxy.

11:55: 🔧 The video shows the labor-intensive process of sanding, grinding, and beveling the keel for fiberglass work.

16:05: 🛠️ The video discusses the use of polyester-based putty for smaller repairs above the waterline, specifically TotalFair.

Recap by Tammy AI

Overthinking leads to good results, they just take longer

Thank you very much for your detailed analysis of the keel work . I found it as I am about to remove the keels from my Solaris catamaran due to , well, they are bulging a little so need removing for a look at what is going on in there .they are also " foam filled " but they do seep water out whenever the boat is lifted out in the winters. I look forward to your follow up videaos , well done .

Very intresting

Thank you for all the details

Ah, just like the good ole days. Nice.